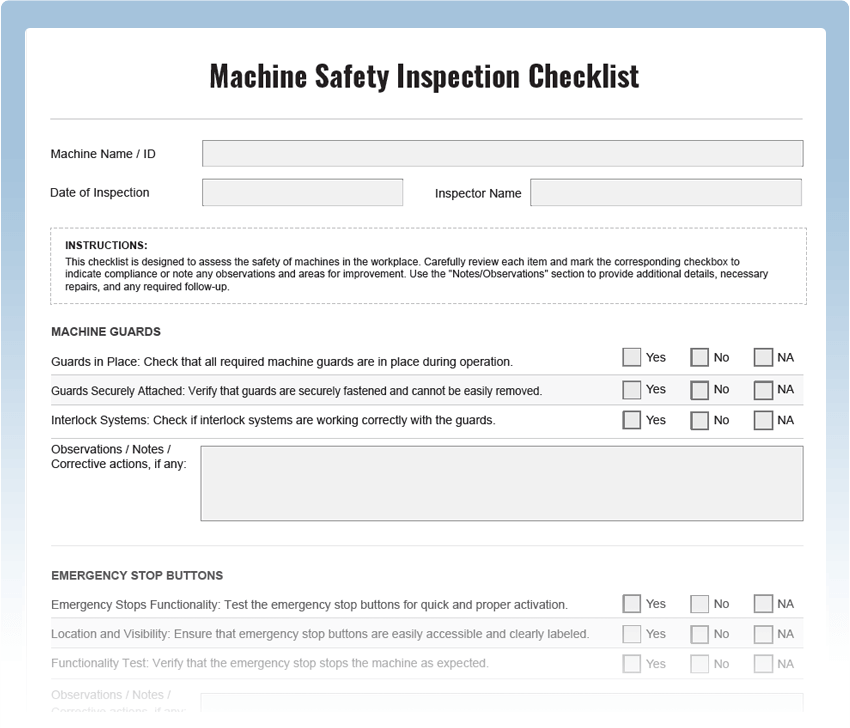

Machine Safety Inspection Checklist

Ensure the safety of your workplace with our comprehensive Machine Safety Inspection Checklist. This free PDF template covers all critical aspects of machine safety, empowering maintenance personnel and safety officers to identify potential hazards, conduct regular inspections, and maintain a secure working environment for employees.

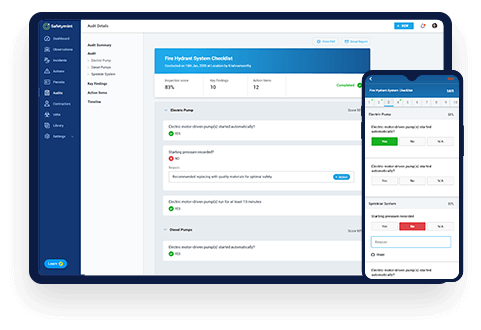

Safetymint Inspection System

- Enhanced interactivity

- Streamlines data entry

- Real-time accessibility

- Access through mobile

What is a Machine Safety Inspection Checklist?

A Machine Safety Inspection Checklist is a systematic tool used to assess the safety conditions of machines and equipment in the workplace. It includes a series of checkpoints designed to inspect various aspects of machine safety, such as guarding, electrical safety, emergency stop functionality, LOTO procedures, and more. Regular machine safety inspections are essential for preventing accidents, protecting workers from hazards, and ensuring compliance with safety regulations.

Key Areas to Inspect in a Machine Safety Inspection:

- Machine Guarding: Check that all machines have appropriate guards in place to prevent contact with moving parts.

- Electrical Safety: Inspect electrical components and wiring for safety and compliance.

- Emergency Stop Functionality: Verify the functionality of emergency stop buttons on machines.

- Lockout/Tagout Procedures: Review the implementation of lockout/tagout procedures during maintenance.

- Safety Labels and Signage: Ensure that machines are properly labeled with safety warnings and instructions.

- Maintenance and Lubrication: Assess the condition of machines and proper lubrication.

Common Machine Safety Inspection Findings:

Frequent issues found during machine safety inspections include:

- Missing Guards: Machines lacking required guards or with damaged guards.

- Faulty Electrical Components: Electrical issues that could lead to electrical shocks or fires.

- Inadequate Lockout/Tagout Procedures: Improperly implemented lockout/tagout procedures during maintenance.

Machine Safety Inspection Best Practices:

- Scheduled Inspections: Conduct routine machine safety inspections at scheduled intervals.

- Operator Training: Train machine operators on safety protocols and proper machine usage.

- Machine Maintenance: Perform regular maintenance to keep machines in safe working condition.

- Safety Awareness Programs: Foster a culture of safety awareness among employees.

- Prompt Repairs: Address and rectify safety issues promptly to prevent accidents.