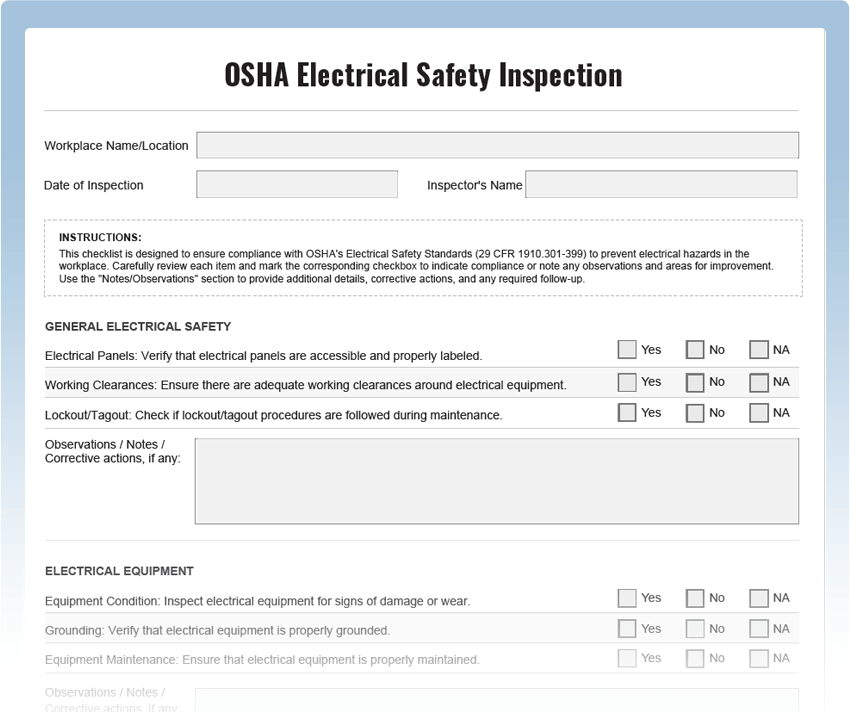

OSHA Electrical Safety Inspection Checklist

Ensure the electrical safety of your workplace with our comprehensive OSHA Electrical Safety Inspection Checklist. This free PDF template covers all critical aspects of electrical safety, empowering you to identify potential hazards, perform regular inspections, and maintain a secure work environment.

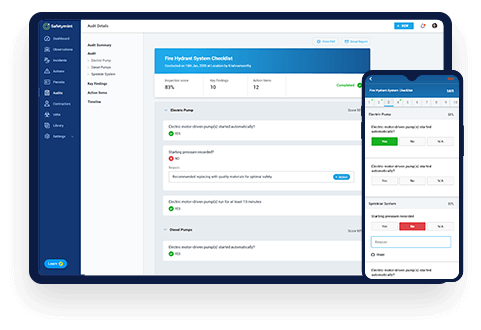

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is an OSHA Electrical Safety Inspection Checklist?

An OSHA Electrical Safety Inspection Checklist is a systematic tool used to assess the safety conditions of electrical systems and equipment in the workplace. It includes a series of checkpoints designed to inspect electrical panels, wiring, outlets, and related safety measures. Regular electrical safety inspections are vital for preventing electrical accidents, protecting employees, and complying with OSHA regulations.

Key Areas to Inspect for Electrical Safety:

- Electrical Panels: Check the condition and accessibility of electrical panels and circuit breakers.

- Wiring and Cables: Inspect wiring and cables for damage, wear, and proper grounding.

- Outlets and Receptacles: Verify the condition and functionality of outlets and receptacles.

- Extension Cords: Assess extension cords for wear, damage, and proper use.

- Electrical Appliances: Inspect electrical appliances for safety labels and potential hazards.

- Ground Fault Circuit Interrupters (GFCIs): Test GFCIs for proper functioning.

Common Electrical Safety Inspection Findings:

Frequent issues found during electrical safety inspections include:

- Exposed Wiring: Wiring that is not properly protected or insulated, posing shock hazards.

- Overloaded Circuits: Circuits with multiple devices drawing more current than they can handle.

- Damaged Outlets: Outlets with loose connections or visible damage.

Electrical Safety Inspection Best Practices:

- Scheduled Inspections: Conduct routine electrical safety inspections at scheduled intervals.

- Arc Flash Hazards: Identify and label areas with arc flash hazards to protect workers.

- Lockout/Tagout Procedures: Implement proper LOTO procedures for electrical work.

- Employee Training: Provide comprehensive electrical safety training to all employees.

- Surge Protection: Use surge protectors to safeguard sensitive electrical equipment.

Also read: Top 10 OSHA inspection checklists