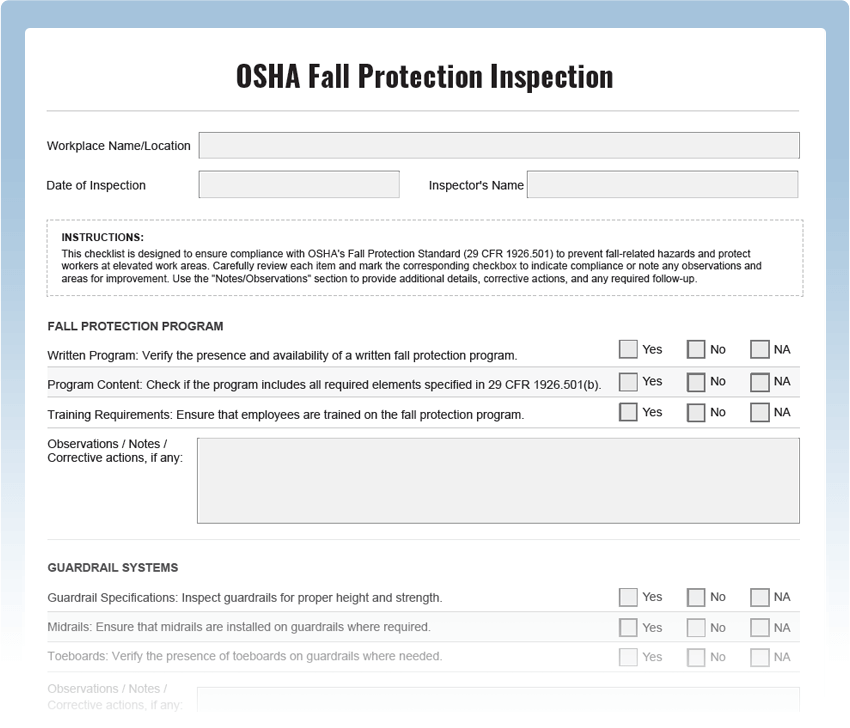

OSHA Fall Protection Inspection Checklist

Ensure the safety of your workers at heights with our comprehensive OSHA Fall Protection Inspection Checklist. This free PDF template covers all critical aspects of fall protection equipment and systems, empowering you to identify potential hazards, perform regular inspections, and maintain a secure work environment.

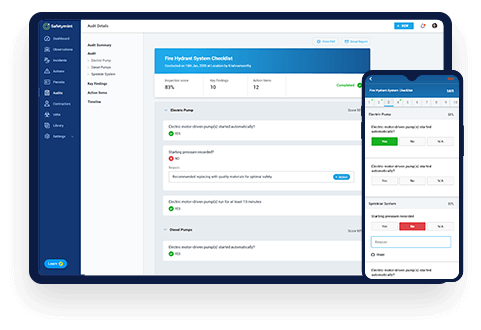

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

Digitize this Checklist on Safetymint

What is an OSHA Fall Protection Inspection Checklist?

An OSHA Fall Protection Inspection Checklist is a systematic tool used to assess the safety conditions of fall protection equipment and systems in the workplace. It includes a series of checkpoints designed to inspect personal fall arrest systems, guardrails, ladders, and other fall protection measures. Regular fall protection inspections are vital for preventing falls, protecting workers, and complying with OSHA regulations.

Key Areas to Inspect for Fall Protection:

- Personal Fall Arrest Systems (PFAS): Check harnesses, lanyards, and connectors for wear or damage.

- Guardrails: Inspect guardrails for stability and secure attachment.

- Anchorage Points: Verify the strength and suitability of anchorage points.

- Safety Nets: Assess safety nets for any holes or damage.

- Ladders: Inspect portable ladders for stability and integrity.

Common Fall Protection Inspection Findings:

Frequent issues found during fall protection inspections include:

- Worn or Damaged Equipment: PFAS with tears, fraying, or broken components.

- Loose Guardrails: Insecurely attached guardrails that may not provide proper protection.

- Defective Anchorage Points: Anchorage points that are not strong enough to support the load.

- Non-compliant Ladders: Ladders that do not meet safety standards or have broken steps.

Fall Protection Inspection Best Practices:

- Scheduled Inspections: Conduct routine fall protection inspections at scheduled intervals.

- Post-Use Checks: Inspect fall protection equipment after each use or fall event.

- Training: Provide comprehensive training on fall protection equipment and safe practices.

- Record-Keeping: Maintain detailed records of inspections and any corrective actions taken.

- Equipment Retirement: Retire any fall protection equipment that fails inspection or reaches its service life.

Also read: Top 10 OSHA inspection checklists