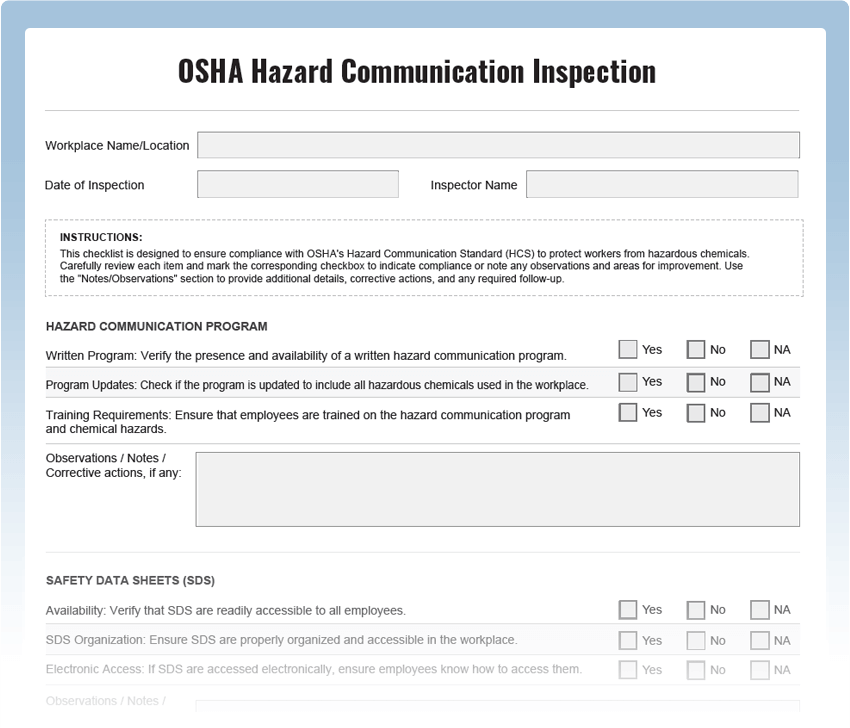

OSHA Hazard Communication Inspection Checklist

Safeguard your workforce from hazardous chemicals with our comprehensive OSHA Hazard Communication Inspection Checklist. This free PDF template covers all critical aspects of hazard communication, empowering you to identify potential risks, perform regular inspections, and maintain a safe work environment.

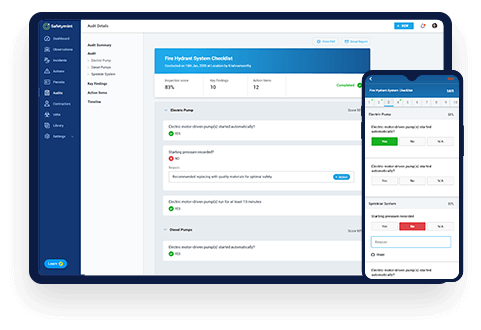

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is an OSHA Hazard Communication Inspection Checklist?

An OSHA Hazard Communication Inspection Checklist is a systematic tool used to assess the effectiveness of a workplace’s hazard communication program. It includes a series of checkpoints designed to inspect chemical labeling, safety data sheets (SDS), employee training, and other hazard communication practices. Regular inspections are essential for preventing chemical-related injuries and illnesses, protecting workers, and complying with OSHA’s Hazard Communication Standard (HCS).

Key Areas to Inspect for Hazard Communication:

- Chemical Labels: Check the presence and accuracy of labels on chemical containers.

- Safety Data Sheets (SDS): Ensure SDS are accessible, up-to-date, and properly maintained.

- Chemical Inventory: Verify that a comprehensive chemical inventory is available and regularly updated.

- Training Records: Review employee training records on hazardous chemicals and their safe handling.

- Container Integrity: Inspect chemical containers for leaks or damage.

- Secondary Container Labeling: Ensure secondary containers are appropriately labeled.

Common Hazard Communication Inspection Findings:

Frequent issues found during hazard communication inspections include:

- Missing or Illegible Labels: Chemical containers without proper labels or faded labels.

- Outdated SDS: Safety Data Sheets that are not current or readily accessible to employees.

- Incomplete Training Records: Lapses in documenting employee training on hazardous chemicals.

Hazard Communication Inspection Best Practices:

- Scheduled Inspections: Conduct routine hazard communication inspections at scheduled intervals.

- Training Updates: Regularly update employee training on new hazardous chemicals and procedures.

- Clear Communication: Ensure hazard information is effectively communicated to all employees.

- Chemical Segregation: Store chemicals properly to prevent incompatible materials from reacting.

Also read: Top 10 OSHA inspection checklists