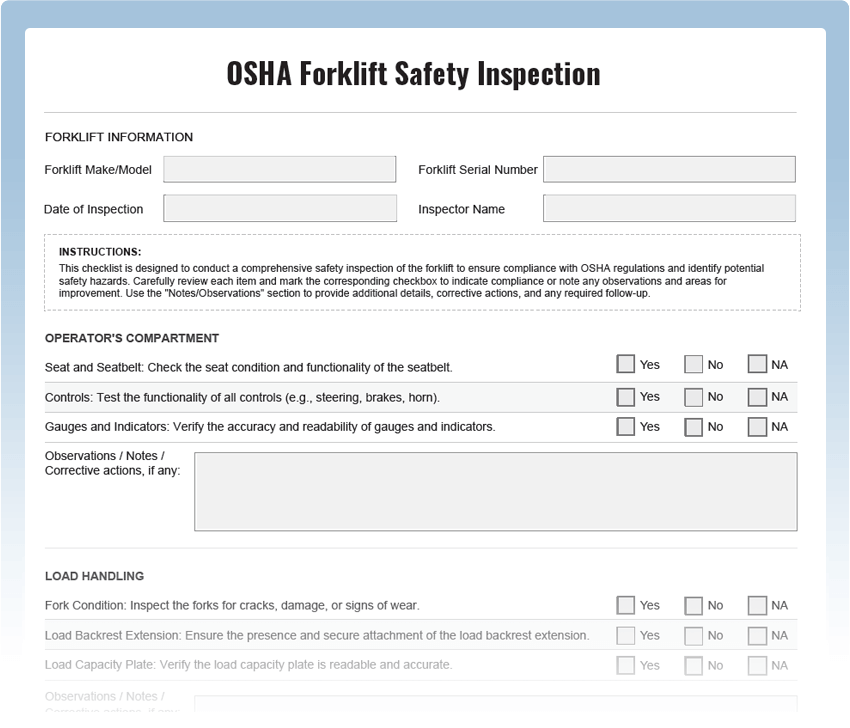

OSHA Forklift Safety Inspection Checklist

Ensure the safe operation of forklifts and compliance with OSHA regulations using our comprehensive Forklift Safety Inspection Checklist. This free PDF template covers all essential aspects of forklift safety, empowering you to identify potential hazards, perform regular inspections, and foster a secure work environment.

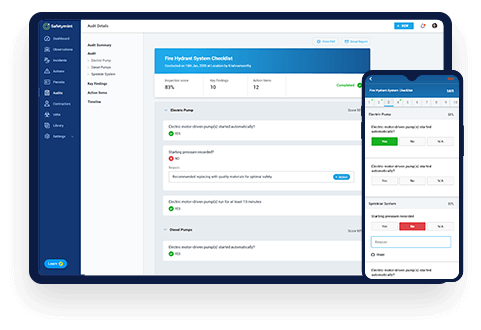

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is an OSHA Forklift Safety Inspection Checklist?

An OSHA Forklift Safety Inspection Checklist is a systematic tool used to assess the safety and functionality of forklifts in the workplace. It includes a series of checkpoints designed to inspect various components and systems of the forklift to ensure they meet OSHA safety standards. Regular forklift safety inspections are crucial for preventing accidents, maintaining equipment performance, and complying with OSHA regulations.

Key Areas to Inspect on the Forklift:

- Operator’s Compartment: Check the condition and functionality of the operator’s seat, seatbelt, and controls.

- Forklift Mast: Inspect the mast assembly, chains, and hydraulic system for any signs of wear or leaks.

- Tires and Wheels: Verify the condition and inflation of the forklift tires and inspect the wheels for damage.

- Braking System: Test the forklift’s braking system for effectiveness and responsiveness.

- Steering and Suspension: Assess the steering system and suspension for smooth operation.

- Battery and Charging: Inspect the battery and charging equipment for safety and proper functioning.

- Horn and Warning Devices: Check the horn, lights, and other warning devices for proper operation.

- Capacity Plate: Ensure that the forklift’s capacity plate is legible and accurate.

Common Forklift Inspection Findings:

Frequent issues found during forklift inspections include:

- Worn Tires: Tires with inadequate tread or damage, affecting traction and stability.

- Fluid Leaks: Hydraulic or coolant leaks, posing environmental hazards and affecting performance.

- Brake Malfunction: Faulty brakes leading to potential accidents and unsafe operation.

- Damaged Forks: Forks with cracks or bends, compromising load stability and posing risks.

Forklift Safety Inspection Best Practices:

- Pre-Operation Checks: Conduct pre-operation inspections before each shift or use.

- Scheduled Maintenance: Implement a regular maintenance schedule and promptly address identified issues.

- Operator Training: Ensure that forklift operators are adequately trained and certified.

- Load Capacity Compliance: Always adhere to the forklift’s load capacity limits.

- Proper Usage: Use the forklift only for its intended purpose and avoid unsafe practices.

Also read: Top 10 OSHA inspection checklists