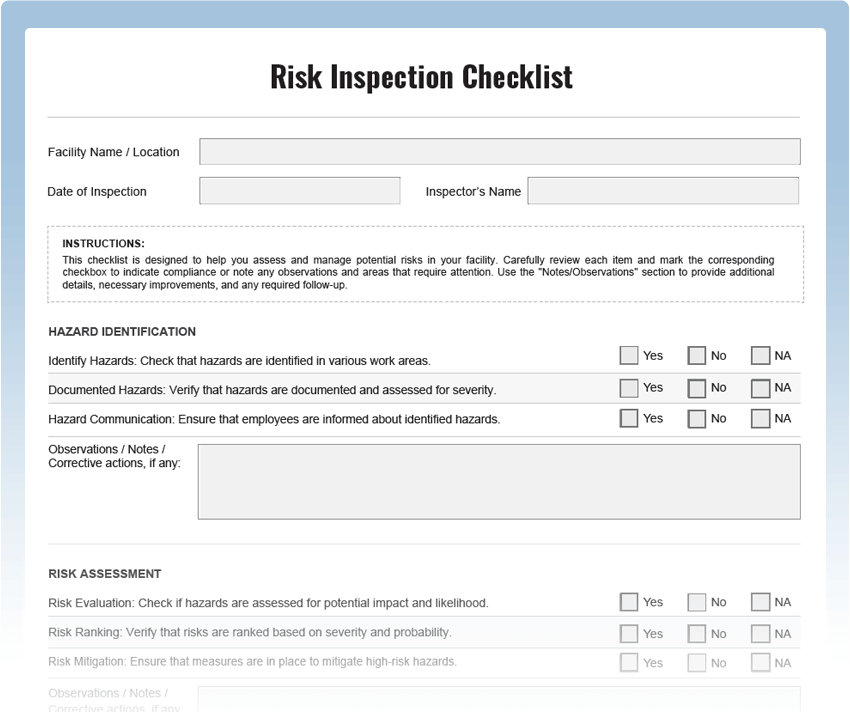

Risk Inspection Checklist

Mitigate potential risks and ensure a secure environment with our comprehensive Risk Inspection Checklist. This free PDF template is designed to help you assess and manage risks within your workplace. By conducting thorough risk inspections, businesses can identify potential hazards, evaluate their severity, and implement preventive measures to safeguard employees, visitors, and assets.

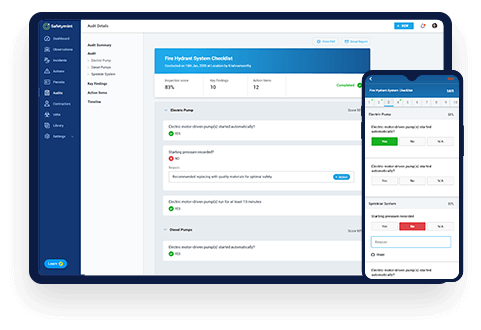

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is a Risk Inspection Checklist?

A Risk Inspection Checklist is a systematic tool used to evaluate and mitigate risks in a workplace. It includes a series of checkpoints designed to assess various aspects of safety, security, and operational processes. Regular risk inspections are vital for identifying hazards, analyzing their potential consequences, and taking proactive steps to reduce risks and enhance overall safety.

Key Areas to Inspect in a Risk Inspection Checklist:

- Physical Hazards: Evaluate potential physical dangers, such as sharp objects, uneven surfaces, and electrical hazards.

- Chemical Hazards: Assess the proper storage, labeling, and handling of hazardous chemicals.

- Fire and Emergency Preparedness: Verify the availability and functionality of fire alarms, extinguishers, and emergency exits.

- Security Measures: Review security protocols, access control, and surveillance systems.

- Equipment and Machinery: Inspect machinery and equipment for safe operation and maintenance.

- Employee Training: Assess the adequacy of employee training for risk awareness and response.

Common Risk Inspection Checklist Findings:

Frequent issues found during risk inspections include:

- Lack of Emergency Plans: Absence of clear emergency response plans and procedures.

- Unsafe Equipment Usage: Improper use or maintenance of machinery and tools.

- Inadequate Training: Employees not adequately trained to recognize and address risks.

Risk Inspection Checklist Best Practices:

- Regular Assessments: Conduct regular risk inspections to stay proactive in risk management.

- Risk Prioritization: Prioritize risks based on severity and potential impact.

- Collaborative Approach: Involve employees in identifying and reporting potential risks.

- Emergency Drills: Conduct regular emergency drills to test preparedness and response.