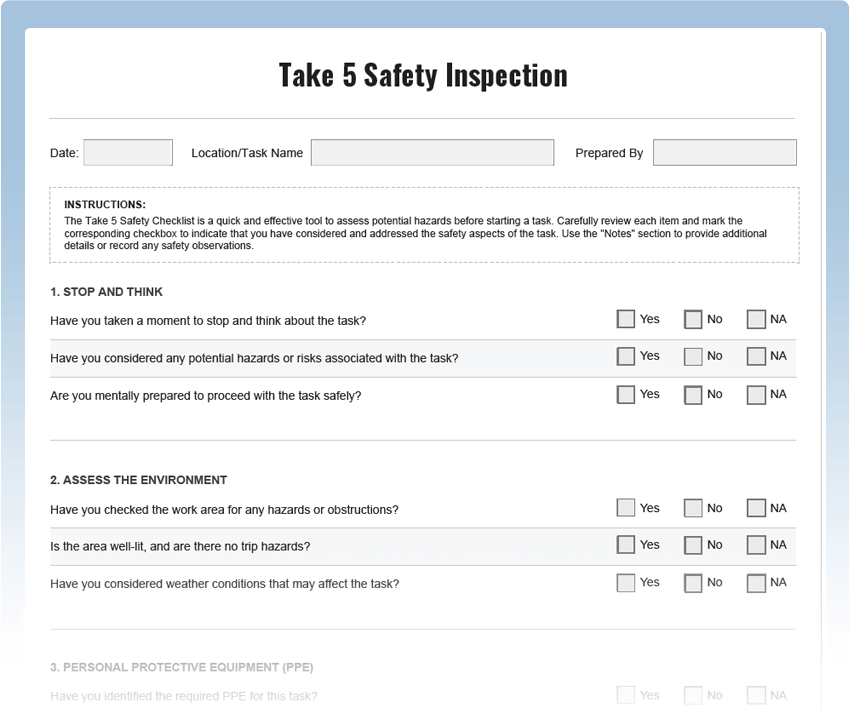

Take 5 Safety Inspection Checklist

Promote a proactive safety culture and empower your employees to conduct quick and effective risk assessments with our comprehensive Take 5 Safety Inspection Checklist. This free PDF template enables your workforce to identify potential hazards, assess risks, and implement necessary control measures before commencing work, ensuring a safer and more secure environment for all.

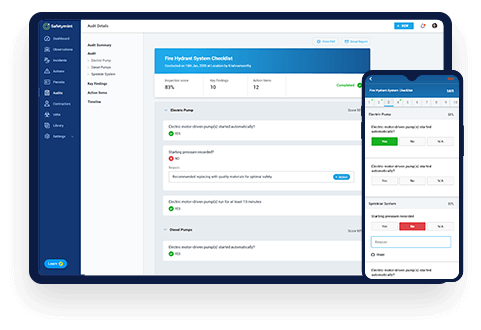

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is a Take 5 Safety Inspection Checklist?

A Take 5 Safety Inspection Checklist is a simple yet powerful tool used to conduct pre-task risk assessments. It involves five critical steps (Stop, Look, Assess, Control, and Proceed) that enable workers to identify potential hazards, evaluate risks, and take appropriate precautions before starting their tasks. Regular use of the Take 5 process enhances safety awareness and reduces the likelihood of incidents.

Key Steps in the Take 5 Safety Inspection:

- Stop: Encourage workers to pause before starting any task to assess potential hazards.

- Look: Observe the work area and surroundings for potential risks and hazards.

- Assess: Evaluate the identified hazards and determine their level of risk.

- Control: Implement appropriate control measures to minimize or eliminate the identified risks.

- Proceed: Only after confirming that all necessary safety measures are in place, proceed with the task.

Common Hazards to Look Out for in the Take 5 Safety Inspection:

The Take 5 Safety Inspection helps identify various hazards, including:

- Slip, Trip, and Fall Hazards: Uneven surfaces, cluttered walkways, and wet floors can cause slips and falls.

- Manual Handling Risks: Heavy lifting without proper techniques can lead to musculoskeletal injuries.

- Chemical Exposure: Improper handling of hazardous substances can result in health issues.

- Electrical Hazards: Contact with live wires or malfunctioning electrical equipment poses risks.

- Working at Heights: Lack of fall protection when working at heights can lead to serious injuries.

Take 5 Safety Inspection Best Practices:

- Training and Education: Train all employees on the Take 5 process and the importance of pre-task risk assessments.

- Consistent Use: Encourage the consistent and widespread use of the Take 5 process across all work areas.

- Supervisor Support: Ensure that supervisors and managers actively participate and promote the Take 5 inspections.

- Feedback and Improvement: Encourage workers to provide feedback on the effectiveness of the Take 5 process and identify areas for improvement.

- Documentation: Maintain records of Take 5 safety inspections and the control measures implemented.